machining surface finish callout

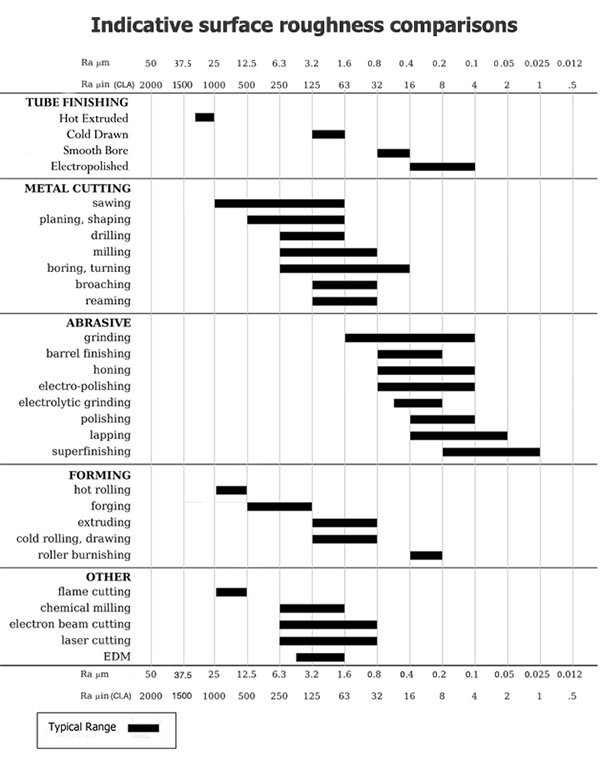

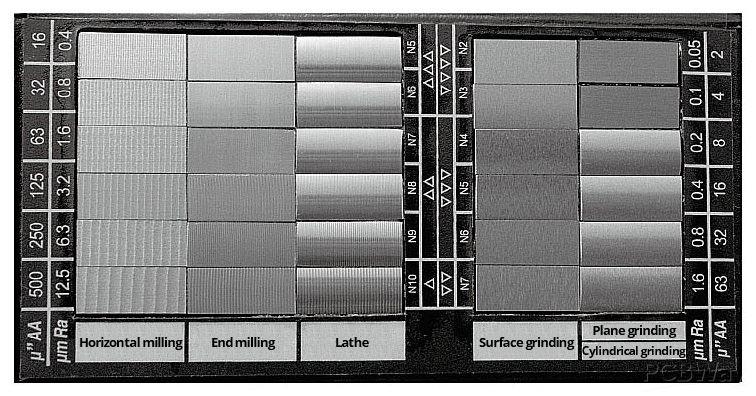

A finishing cutting pass can be applied to reduce the roughness of a surface down to 16 08 or 04 μm 63 32 or 16 μin. For machining processes such as milling turning and grinding factors such as cutting tool selection machine tool condition toolpath parameters feeds speeds tool.

Complete Surface Finish Chart Symbols Roughness Conversion Tables

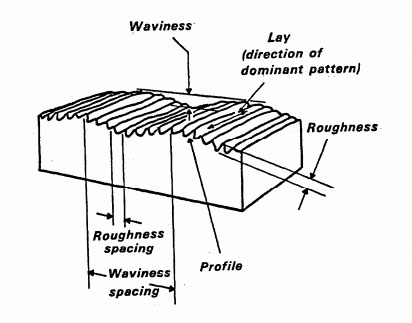

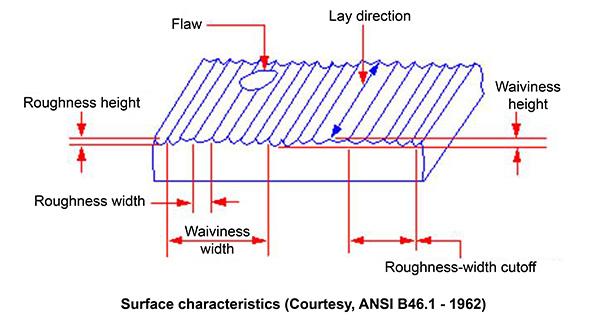

Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping.

. This will increase the cost of producing a part as extra machining steps and tighter quality control are required. Ones rms is to mentally multiply the metric value by 40. DennisP Mechanical 21 Jun 07 0457.

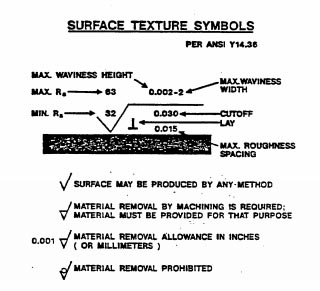

Yes to Teds answer. A If the surface roughness is obtained by any production method other than machining the value of surface rough necessary say125μm is indicated in the basic symbol as shown in figure B. Piston rods are generally hard chrome plated.

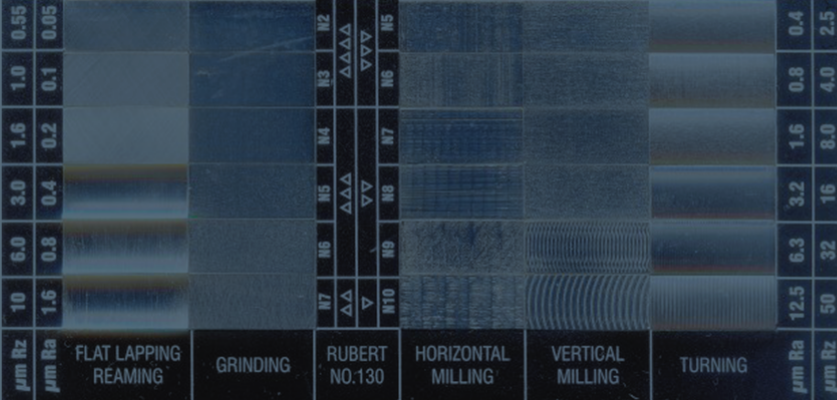

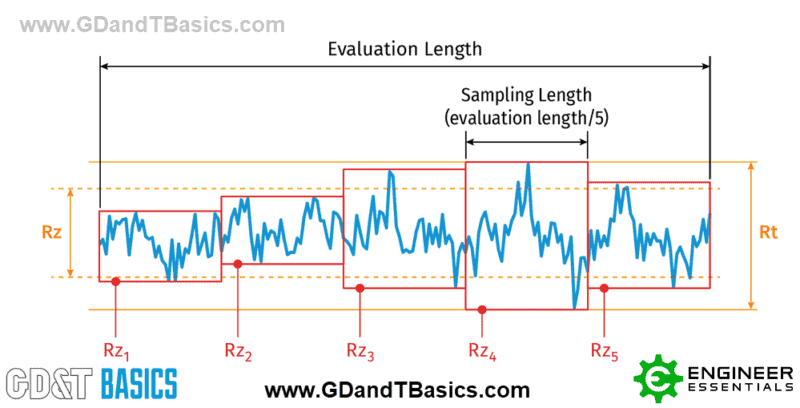

As a rule of thumb λc should be set to about five times this spacing. You can get a N9 finish for sure with a bandsaw N8 if you are using a good blade with fine teeth. 22 rows The surface finish comparator for milling turning reaming and grinding.

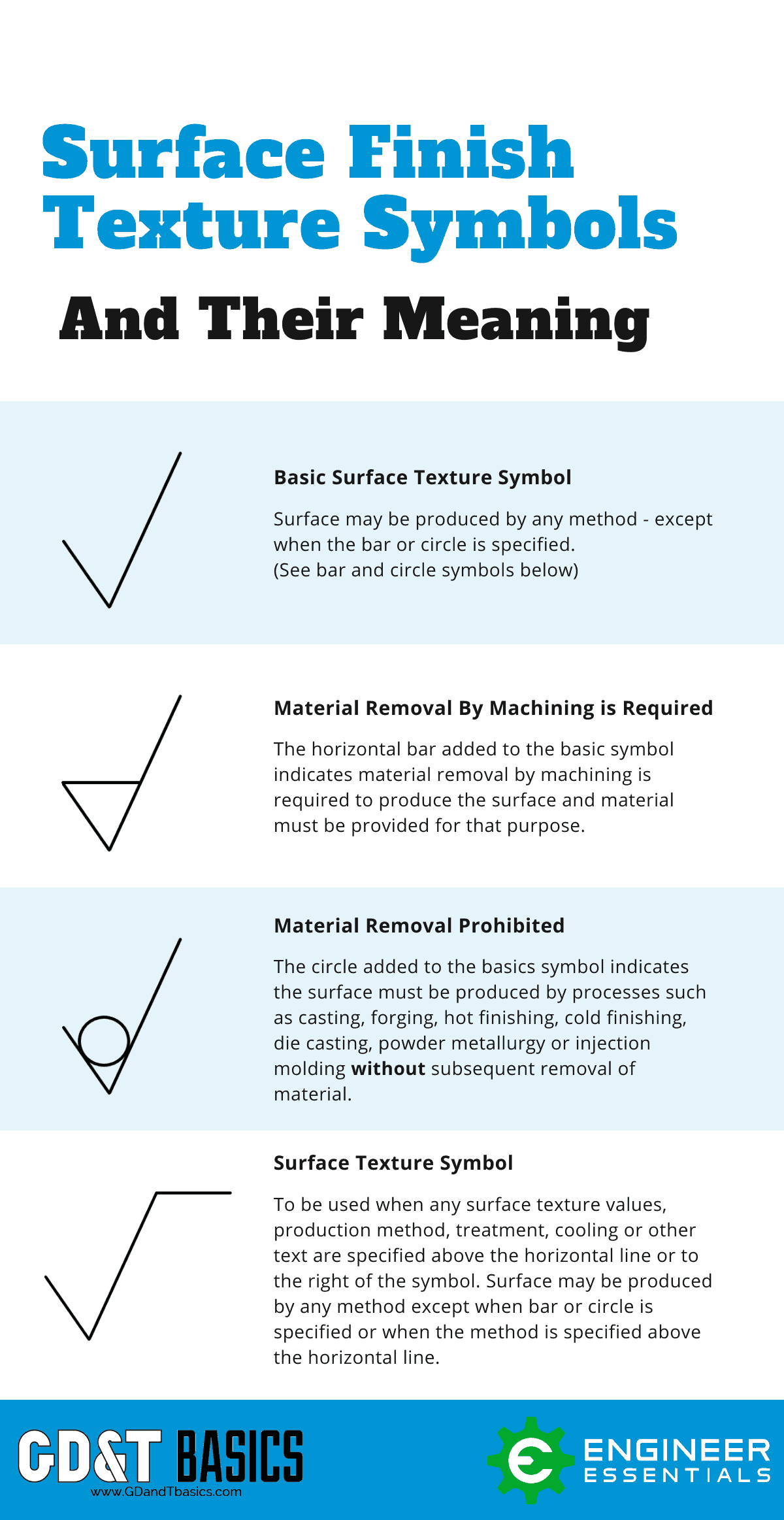

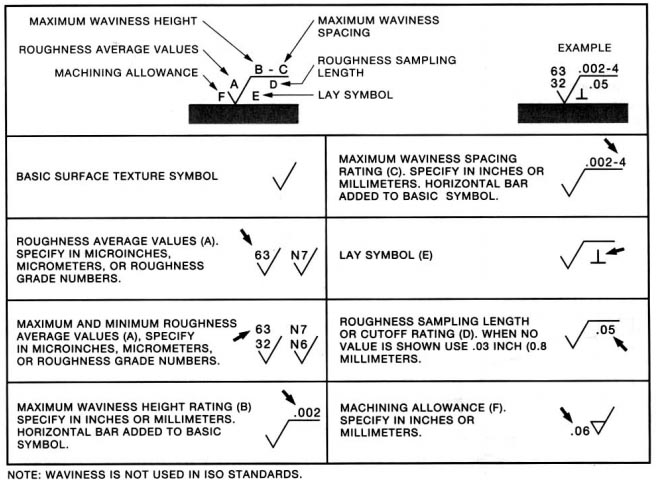

This is done through measurements by using a unit known as Ra. Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designers intent. Passband or sampling length and surface texture parameter symbol and value.

Machining N9 250 63 N10 500 125 Rough Machining N11 1000 25 N12 2000. 2 Turning boring planing milling scraping 1 2 pointscm2 drawing grinding filing rolling milling. N New ISO grade scale numbers.

N6 finish will need to be machined. Publicly reply to Roger Morgan. Browse Our Wide Selection of Products Speak to One of Our Surface Finishing Specialists.

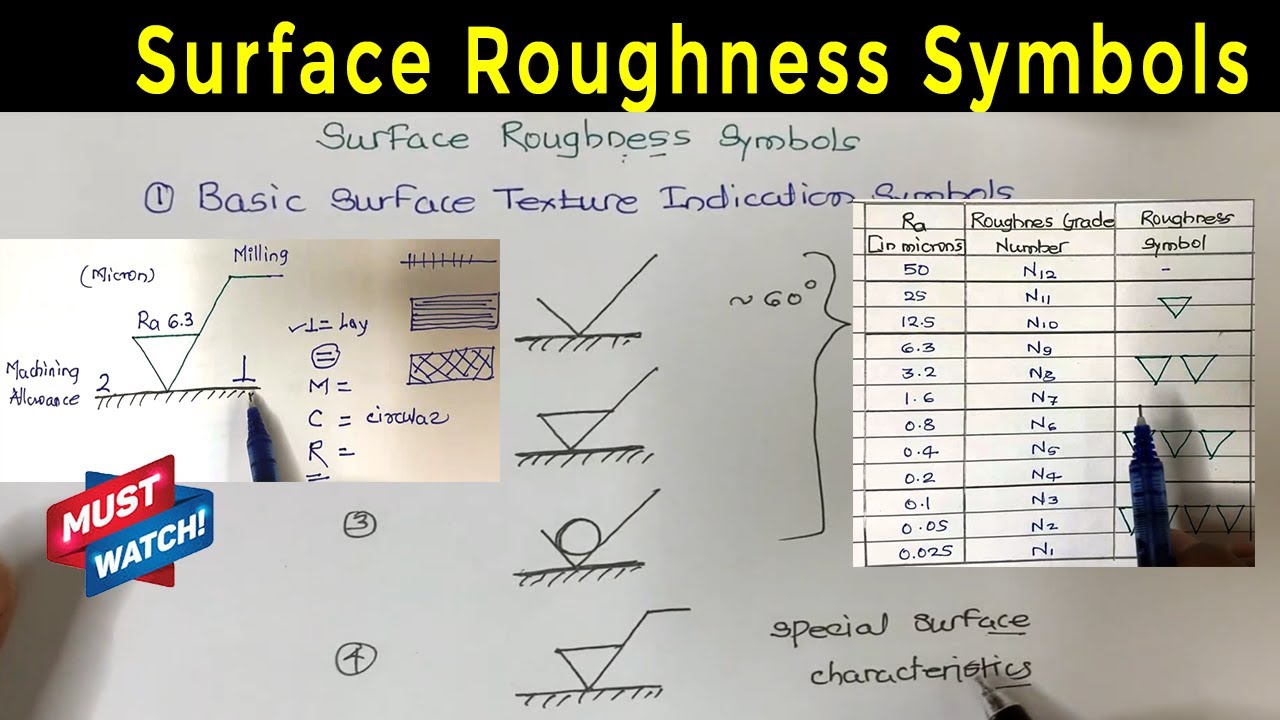

Finish Symbol N Finish R a μinch R a μm Super finishing. The surface roughness is the measure of the total spaced irregularities on the surface. 15 rows Surface finish specification and comparison.

It also depicts the number of peaks and valleys on a surface. For additional information see ASME B461. Perfect the Appearance Quality of Your Work.

If Y145 its called Surface Texture. Yide Casting is a leading iron foundry provide both casting service and machining service equipped with imported advanced machining machines in our machining workshop if you have both casting and machining demands Yide casting is a good choice for you we promise good. Rt Roughness Tool in microns.

If cut-off value is too low the measured roughness values will be. The lower the number the lower the irregularities implying low surface roughness and a better surface finish. 1 Processing traces are slightly visible.

Q A or Comment on THIS thread SEARCH for Threads about. Ad Electropolishing Oxygen Cleaning Passivating Polishing Services. The measure of the total space irregularities on the surface metal is known as Surface Roughness.

B If the surface roughness is. If the part is metric then the 82 most likely means an 82 micron Ra finish. This gives an excellent tribological surface and provided the rods are produced by an established supplier within a surface finish range of 01 to 03 μm Ra 4-12 μin Ra no major problem should ensue.

To improve the understanding and application of Roundness and Surface. The standard as-machined surface roughness is 32 μm 125 μin. PGI standard machining surface finish is 125RMS unless otherwise specified.

We offer standard and bespoke Training Courses in Surface Finish and Roundness coupled with contact and non-contact Instrument Operator Training. For example 16 63 rms 32 125 rms and 63 250 rms. The indication of surface roughness values in the surface finish symbols are shown the figure A.

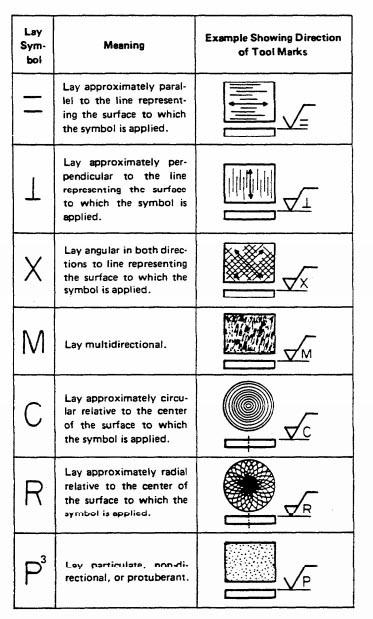

If it is a turned surface then the C probably denotes a circular lay to the finish. 1821 Surface Texture Methods of specifying surface texture requirements are covered in ASME Y1436M. This minimum length of 08 mm ensures that there is enough roughness to perform the mathematical calculation of roughness.

Valleys caused by the machining process denoted RSm. The Ra is calculated by taking a deviation from the mean of the surface plane and then applying it in microinches thus determining the roughness. If its an inch print then it woulod be 82 microinches which would need to be a ground surface.

With that being said the finer the surface finish the longer cycle. There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface. 3 Connecting with other parts does not form a matching surface such as The end.

Standard machining surface finish historically was 125ra or greater however over the years with the advancement of CNC machines and tooling we can now generate machined finished as fine as 8ra. Our standard Blanchard ground finish is 64RMS and our standard surface grinding finish is 32RMS. - Green Bay Wisconsin.

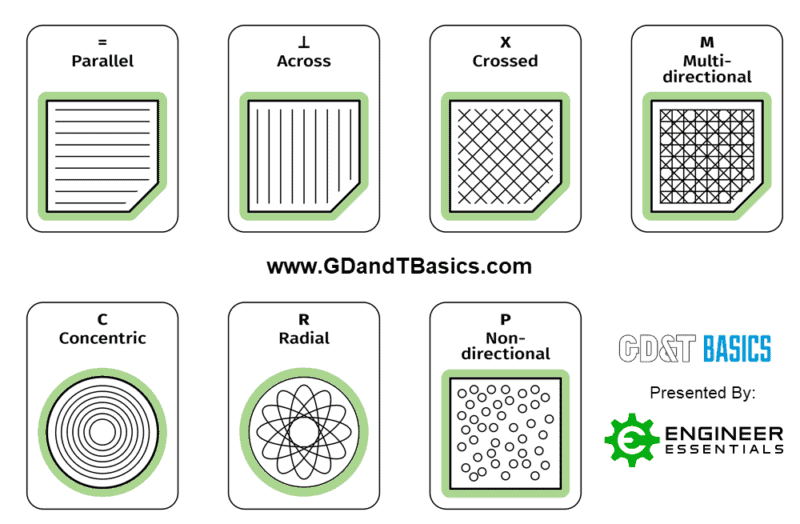

In our grinding shop we most commonly discuss surface finish standards of 64RMS and 32RMS. By triangle symbol. It is a measure of the complete texture of a products surface that is defined by three characteristics of surface roughness waviness and lay.

When professionals refer to surface finish it is often surface. 22 rows As for machining to iron and steel castings the surface finish smooth degree is. Since the surface finish requirement is 16 microns national specifications recommend a cut-off value for this roughness value of 08 mm in length.

Complete Guide to Machining Blueprint Symbols. May 6 2022 May 5 2022 by Brandon Fowler. Ad Deburr Grind Blend Polish.

A symbol for defining the surface finish of a part. It is important to understand the cost of a finish callout. Definition of Surface Finish.

And for metric triangle callouts you can approximate one triangle 250 finish two triangles 125 finish and three triangles 32 to 63 finish. Determining the surface roughness is the first step that should occur after plastic parts are machined. An easy way to convert metric surface call outs to standard US.

The hardness target should be at least 67 Rockwell C 900 HV10. N1 1 0025 Lapping. This surface roughness indication method pictorially displays information such as the surface roughness value cutoff value sampling length machining method crease direction symbol and surface waviness on the surface indication symbol as shown below.

Complete Surface Finish Chart Symbols Roughness Conversion Tables Surface Surface Finish Symbols Surface Finish

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Why Use A Surface Finish Chart Metal Surface Finish

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Pin On Solidworks Sheet Metal Design

The Basics Of Surface Finish Gd T Basics

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Finish Surface Roughness It S Indications Symbols

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Finish Surface Roughness Symbols Charts Callouts Costs

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

What Is Surface Finish Units Symbols Chart Engineering Choice

Complete Surface Finish Chart Symbols Roughness Conversion Tables

The Basics Of Surface Finish Gd T Basics

Surface Finish Surface Roughness Symbols Charts Callouts Costs